How 3D Printing is Transforming Dental Prosthetics: Advancements, Benefits, and Future Outlook

Posted on: 18/06/2025

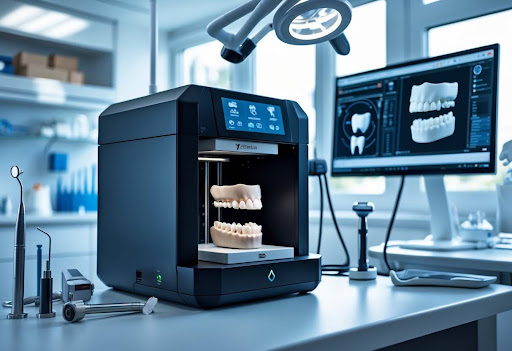

3D printing is rapidly changing dental prosthetics by providing unmatched accuracy, speed, and personalisation. With this technology, you can now get crowns, bridges, and dentures tailored to your unique dental anatomy, often in less time than traditional methods. Even materials are evolving, so printed prosthetics can be lighter, more comfortable, and closely matched to your natural teeth.

Imagine needing a replacement tooth and walking out with a precise fit within a few hours. Modern 3D printers use specialised resins and composites, allowing dental labs to craft items layer by layer at a microscopic scale, sometimes as thin as a sheet of paper. Tips like keeping digital scans up-to-date and discussing custom colour options with your dentist help ensure your 3D printed prosthetic looks and feels natural.

This digital approach not only shortens waiting times but streamlines adjustments and remakes, reducing chair time for you. Fun fact: a single dental prosthesis can be printed in about two hours (less than the full duration of a football event), transforming both the patient experience and what’s possible in dental care.

3D printing is reshaping dental prosthetics by introducing precise fabrication, enhanced personalisation, and accelerated production timelines. The advent of digital workflows and novel materials now enables you to benefit from durable, well-fitting prosthetics made with efficiency and accuracy.

In the late 19th century, technicians crafted dental prostheses by hand using wax and metal. Every denture or crown required painstaking manual shaping, which made consistent results challenging. Early prosthetics relied on materials like ivory and vulcanite until acrylics arrived in the 20th century.

By the 1980s, the emergence of computer-aided design (CAD) and computer-aided manufacturing (CAM) started to modernise dental laboratories. Yet, even CAD/CAM still involved subtractive processes, such as milling, which removed material from a solid block. This limited the detail and complexity you could achieve.

Today, 3D printing, also known as additive manufacturing, allows intricate customisation by adding material layer by layer, rather than carving it away. You get prosthetics that can match subtle dental anatomy improvements over what manual methods ever allowed.

Traditional dental prosthetics require multiple visits and time-intensive steps. These steps include making physical impressions, pouring plaster models, and hand-finishing each piece. Delays frequently occur due to trial-and-error adjustments and remakes.

In contrast, 3D printing streamlines the workflow. The process begins with a digital scan of your teeth, often using intraoral scanners. This data feeds directly into design software, enabling rapid modifications and previews. Printers use materials designed specifically for dental use, from resins to metals.

Some notable milestones have marked the rise of 3D printing in dental prosthetics:

A helpful tip: Stay informed about the latest printable materials, as ongoing innovations frequently lead to stronger, more lifelike prosthetics. Additionally, digital records make future replacements and repairs much easier for both you and your dental practice.

Different 3D printing methods enable the precise and efficient production of dental prosthetics, each with its own benefits and best-use scenarios. These technologies determine the quality, speed, and materials that can be used for crowns, bridges, dentures, and more.

Stereolithography (SLA) uses a laser to cure liquid resin into solid plastic models, layer by layer. SLA is valued for its high accuracy and exceptionally smooth surface finishes, making it popular for creating precise dental models, crowns, and surgical guides.

With resolutions up to 25 microns (about 0.001 inches), SLA can reproduce fine details often needed in dental frameworks. The technology supports a range of biocompatible resins, such as those suitable for temporary crowns or surgical templates.

A fun fact: SLA printers can create full dental arches in just a few hours. Make sure to store the resins properly and handle printed parts with gloves, as uncured resin can be sticky and sensitive to light.

Digital Light Processing (DLP) is similar to SLA but uses a projector instead of a laser to cure resin. This method allows for even faster print times because each entire layer is cured at once, rather than tracing it line by line.

DLP provides excellent print resolution and is widely used for fabricating dental prosthetics like dentures, aligners, and crowns. Materials come in various shades and strengths, giving you flexibility in creating custom solutions.

DLP printers also require less maintenance than some other 3D printers. For best results, always calibrate the projector before printing and use the manufacturer’s recommended resins to maintain part quality and patient safety.

Selective Laser Sintering (SLS) employs a laser to fuse powdered materials—such as nylon or metal—layer by layer. This technology stands out for its ability to print strong, durable prosthetic frameworks with complex geometries that aren’t possible with traditional moulding techniques.

SLS is ideal for fabricating partial denture frameworks, custom abutments, and metal substructures. With no need for support structures during printing, even intricate shapes are easy to produce.

You can use SLS to print metal crowns and custom-fitting prosthetic parts that are lightweight yet resilient. Always follow post-processing steps like sandblasting or polishing to achieve a smooth, usable finish.

Material Jetting

Material Jetting, often compared to inkjet printing, dispenses thousands of micro-droplets of resin onto the print bed, then hardens each layer with UV light. This method allows you to create highly detailed, multi-material, and multi-colour dental prosthetics.

Material Jetting excels in fabricating realistic models for patient education, surgical planning, and temporary prosthetics. Its layer thickness can reach up to 16 microns (about 0.0006 inches), resulting in exceptional detail.

Keep in mind that these printers usually require frequent cleaning and maintenance. When printing multi-material prosthetics, always verify the compatibility of the selected resins to avoid warping or bonding issues. Material Jetting also offers the unique advantage of simultaneously printing soft and hard structures for more anatomical models.

3D printing allows for faster treatments, greater accuracy, and tailored solutions in restorative dental care. You'll find the technology supports a range of prosthetic needs, from precisely fitted crowns to complex implant systems.

Crowns and Bridges

With 3D printing, your crowns and bridges can be designed and produced in as little as a single day. Dentists use intraoral scanners to capture high-resolution images of your teeth, allowing for digital modelling and immediate fabrication.

This process reduces human error and shortens chair time significantly. Materials such as resin and ceramics are employed to achieve both durability and a natural appearance. After printing, the prosthetics require minimal finishing before placement.

One standout benefit: If you break a bridge or crown, digital files make replacement simple and fast. It also allows for greater customisation, important for comfort and bite alignment.

Tip: Ask your dentist if their practice uses digital impressions, as they improve fit and reduce discomfort compared to traditional moulds.

3D printing offers fully customisable dentures that adapt closely to your bone structure and oral anatomy. This method eliminates the trial-and-error adjustments common with conventional dentures.

During production, the dentist scans your mouth, then designs the base and artificial teeth using software. The printed result comes with improved fit and stability, so sores and slipping are less likely.

You’ll also benefit from enhanced aesthetics, with teeth matched to your desired shade and shape. In case you lose your dentures, having the digital blueprint available means you won’t need repeat impressions.

Fun fact: Some practices can print a temporary denture in just a few hours—ideal if you need a quick solution.

When placing dental implants, precision is critical, and 3D printed surgical guides help your dentist achieve it. These guides are tailored for your mouth’s exact contours, directing tools accurately during surgery.

The planning phase relies on digital imaging, which is used to design the guide and pre-plan implant positions. This can reduce surgery time and lower your risk for complications.

3D printing also helps create custom abutments and temporary implant restorations. The made-to-measure approach leads to better integration with your bone and faster healing.

Hint: If you’re considering implants, ask about 3D printed guides—they improve predictability and safety during surgery.

3D printing introduces new levels of precision, speed, and flexibility to dental prosthetics manufacturing. However, it also brings unique considerations, such as equipment costs and the need for specialised training.

With 3D printing, you can offer dental prosthetics that fit your patient’s mouth with remarkable accuracy. Digital scanning and design allow for truly custom crowns, bridges, dentures, and aligners that match an individual’s anatomy.

The use of digital workflows reduces the risk of manual errors. Even the most complex cases, such as full-arch restorations, can benefit from digital modelling and additive manufacturing. This leads to improved clinical outcomes and often increases patient satisfaction.

A fun fact: Digital impressions used for 3D design are often more comfortable for patients compared to traditional moulds. You can tweak and adjust the model digitally before manufacturing, saving both time and resources.

3D printing streamlines the process from scan to finished prosthetic. Once digital data is captured, you can print a prototype or a final restoration within hours, rather than waiting days or weeks for traditional methods.

Same-day prosthetics become feasible, letting patients save time with fewer appointments. Changes and adjustments are easier, as you simply edit the digital file and reprint, without remoulding or recasting.

While speed depends on the printer and material, a typical dental crown can be ready in under two hours. For clinics, this means you can handle more cases in less time, increasing both efficiency and patient throughput.

Although the initial investment for a high-quality dental 3D printer can be substantial — often upwards of £12,000 ($15,000) — running costs per print are typically lower than traditional lab methods.

You will benefit from reduced material waste, especially as additive manufacturing uses only what is required. Labour costs also decrease, as fewer manual steps are needed.

However, ongoing expenses include materials, maintenance, and training staff to operate and design using the software. Choosing the right 3D printer and material for your specific workflows is crucial to maximising savings and avoiding hidden costs.

With rapid progress in dental materials, digital workflows, and manufacturing standards, 3D printing is set to make dental prosthetics more precise, accessible, and tailored. The focus has shifted towards biocompatible innovation, full digital integration, and robust safety measures.

You can expect to see a broader range of printable dental materials, each engineered for specific prosthodontic requirements. Biocompatibility and mechanical strength remain key, with new resins and polymers designed to mimic natural tooth structure and gum tissue.

Ceramic- and metal-based printing is advancing, allowing custom crowns, bridges, and partial dentures with high wear resistance. Materials like hybrid composites provide greater flexibility and improved aesthetics. Companies have started releasing printable materials that can withstand daily oral forces and temperature changes from food and drinks.

Tip: Always verify that the material used in your dental prosthetic is certified for medical use, and if you have allergies, discuss options with your dentist. For dental labs, investing in versatile printers compatible with a wide array of resins and metals will help you adapt to changing patient needs and requests.

A fully digital workflow — from intraoral scanning to CAD/CAM design and 3D printing — is becoming standard in modern dental clinics. You can now get prosthetics designed and fitted with fewer appointments and more predictability in final fit and appearance.

3D-printed surgical guides, custom trays, and root analogue implants have become more prevalent. These tools help reduce chair time and improve treatment outcomes. By combining CBCT scans and digital impressions, precise geometries are created to match individual mouths, minimising the need for manual adjustments later.

For dental professionals, upgrading to digital impression systems and training in software design bring major productivity gains. This not only speeds up turnaround but also reduces the risk of human error. Clinics embracing digital dentistry gain a strong competitive edge.

Strict regulatory oversight ensures ongoing improvements in patient safety for 3D printed dental prosthetics. All materials and production processes must comply with local and international medical device standards. The Medicines and Healthcare products Regulatory Agency (MHRA) in the UK, for example, evaluates both material biocompatibility and the accuracy of digital workflows.

Ethical considerations include data privacy for personal digital dental records and the proper handling of patient-specific files. Dentists must store digital scans securely and comply with all applicable consent and data protection regulations.

You should also be aware of certification requirements before purchasing printed prosthetics. Always ask your dental provider about approval status, traceability, and warranties for any device made using 3D printing in dentistry.

You can now receive dental prosthetics that fit better, look more natural, and are created much faster than before. Modern 3D printing streamlines dental workflows, expands material choices, and makes customisation much easier for both patients and dentists.

3D printing allows dental technicians to produce crowns, bridges, and dentures with higher precision than traditional techniques. The digital workflow lets you preview dental prosthetics using virtual models before fabrication even begins.

It is now possible to fabricate multiple components at the same time, speeding up the entire process. Many labs use 3D scanning and digital design, meaning you can get replacements that fit accurately the first time.

With digital impressions and 3D printers, dental implants are created to match your exact oral anatomy. 3D printing can produce surgical guides for implant placement, improving accuracy and safety.

Dentists can print models for diagnosis, surgical templates, and final prosthetics, all using your unique data. Rapid prototyping also allows for quicker adjustments and remakes if needed.

You benefit from shorter turnaround times—sometimes same-day or next-day delivery of crowns and bridges. 3D printing also reduces material waste and streamlines manual steps, making treatment more cost-effective.

New materials, like printable ceramics and resins, come in shades and translucencies that closely replicate real teeth. 3D printers can layer these precisely, producing natural-looking results.

You can experience less time in the dental chair because digital impressions replace messy moulds. Appointments often require fewer visits since design tweaks and final adjustments happen rapidly on a computer.

Printed prosthetics generally offer a better fit, meaning fewer modifications are required once your new teeth are ready. Patients also report greater comfort and more confident smiles when prosthetics match their natural teeth shape and colour.

Dental 3D printers primarily use biocompatible resins, hybrid composites, and ceramics. These materials are chosen because they are strong, durable, and safe for long-term wear in your mouth.

Ceramic and zirconia parts are suitable for visible teeth thanks to their natural colour and shine. Resins allow flexible printing and are perfect for creating denture bases and temporary crowns.

Your dental restoration begins with digital scanning, capturing the exact shape of your gums and teeth. Technicians design your prosthetic down to a fraction of a millimetre, ensuring a proper bite and improved aesthetics.

The customisation extends to shade matching, anatomical contours, and even how your teeth function when you chew. If you have unique dental needs, such as a challenging bite or missing several teeth, 3D printing can create a solution tailored just for you.

Imagine needing a replacement tooth and walking out with a precise fit within a few hours. Modern 3D printers use specialised resins and composites, allowing dental labs to craft items layer by layer at a microscopic scale, sometimes as thin as a sheet of paper. Tips like keeping digital scans up-to-date and discussing custom colour options with your dentist help ensure your 3D printed prosthetic looks and feels natural.

This digital approach not only shortens waiting times but streamlines adjustments and remakes, reducing chair time for you. Fun fact: a single dental prosthesis can be printed in about two hours (less than the full duration of a football event), transforming both the patient experience and what’s possible in dental care.

The Evolution of Dental Prosthetics with 3D Printing

3D printing is reshaping dental prosthetics by introducing precise fabrication, enhanced personalisation, and accelerated production timelines. The advent of digital workflows and novel materials now enables you to benefit from durable, well-fitting prosthetics made with efficiency and accuracy.

Historical Perspective

In the late 19th century, technicians crafted dental prostheses by hand using wax and metal. Every denture or crown required painstaking manual shaping, which made consistent results challenging. Early prosthetics relied on materials like ivory and vulcanite until acrylics arrived in the 20th century.

By the 1980s, the emergence of computer-aided design (CAD) and computer-aided manufacturing (CAM) started to modernise dental laboratories. Yet, even CAD/CAM still involved subtractive processes, such as milling, which removed material from a solid block. This limited the detail and complexity you could achieve.

Today, 3D printing, also known as additive manufacturing, allows intricate customisation by adding material layer by layer, rather than carving it away. You get prosthetics that can match subtle dental anatomy improvements over what manual methods ever allowed.

Comparison of Traditional and 3D Printing Methods

Traditional dental prosthetics require multiple visits and time-intensive steps. These steps include making physical impressions, pouring plaster models, and hand-finishing each piece. Delays frequently occur due to trial-and-error adjustments and remakes.

In contrast, 3D printing streamlines the workflow. The process begins with a digital scan of your teeth, often using intraoral scanners. This data feeds directly into design software, enabling rapid modifications and previews. Printers use materials designed specifically for dental use, from resins to metals.

Milestones in Adoption

Some notable milestones have marked the rise of 3D printing in dental prosthetics:

- 2010s: Mainstream dental labs began investing in 3D printing for models and surgical guides.

- 2015: Materials specifically tailored for final dentures and crowns became widely available.

- 2018: Full-scale digital workflows allowed you to receive try-in prosthetics within just 24–48 hours.

- Present: Metal frameworks, denture bases, and temporary as well as permanent crowns are routinely printed.

A helpful tip: Stay informed about the latest printable materials, as ongoing innovations frequently lead to stronger, more lifelike prosthetics. Additionally, digital records make future replacements and repairs much easier for both you and your dental practice.

3D Printing Technologies Used in Dental Prosthetics

Different 3D printing methods enable the precise and efficient production of dental prosthetics, each with its own benefits and best-use scenarios. These technologies determine the quality, speed, and materials that can be used for crowns, bridges, dentures, and more.

Stereolithography (SLA)

Stereolithography (SLA) uses a laser to cure liquid resin into solid plastic models, layer by layer. SLA is valued for its high accuracy and exceptionally smooth surface finishes, making it popular for creating precise dental models, crowns, and surgical guides.

With resolutions up to 25 microns (about 0.001 inches), SLA can reproduce fine details often needed in dental frameworks. The technology supports a range of biocompatible resins, such as those suitable for temporary crowns or surgical templates.

A fun fact: SLA printers can create full dental arches in just a few hours. Make sure to store the resins properly and handle printed parts with gloves, as uncured resin can be sticky and sensitive to light.

Digital Light Processing (DLP)

Digital Light Processing (DLP) is similar to SLA but uses a projector instead of a laser to cure resin. This method allows for even faster print times because each entire layer is cured at once, rather than tracing it line by line.

DLP provides excellent print resolution and is widely used for fabricating dental prosthetics like dentures, aligners, and crowns. Materials come in various shades and strengths, giving you flexibility in creating custom solutions.

DLP printers also require less maintenance than some other 3D printers. For best results, always calibrate the projector before printing and use the manufacturer’s recommended resins to maintain part quality and patient safety.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) employs a laser to fuse powdered materials—such as nylon or metal—layer by layer. This technology stands out for its ability to print strong, durable prosthetic frameworks with complex geometries that aren’t possible with traditional moulding techniques.

SLS is ideal for fabricating partial denture frameworks, custom abutments, and metal substructures. With no need for support structures during printing, even intricate shapes are easy to produce.

You can use SLS to print metal crowns and custom-fitting prosthetic parts that are lightweight yet resilient. Always follow post-processing steps like sandblasting or polishing to achieve a smooth, usable finish.

Material Jetting

Material Jetting, often compared to inkjet printing, dispenses thousands of micro-droplets of resin onto the print bed, then hardens each layer with UV light. This method allows you to create highly detailed, multi-material, and multi-colour dental prosthetics.

Material Jetting excels in fabricating realistic models for patient education, surgical planning, and temporary prosthetics. Its layer thickness can reach up to 16 microns (about 0.0006 inches), resulting in exceptional detail.

Keep in mind that these printers usually require frequent cleaning and maintenance. When printing multi-material prosthetics, always verify the compatibility of the selected resins to avoid warping or bonding issues. Material Jetting also offers the unique advantage of simultaneously printing soft and hard structures for more anatomical models.

Applications in Restorative Dentistry

3D printing allows for faster treatments, greater accuracy, and tailored solutions in restorative dental care. You'll find the technology supports a range of prosthetic needs, from precisely fitted crowns to complex implant systems.

Crowns and Bridges

With 3D printing, your crowns and bridges can be designed and produced in as little as a single day. Dentists use intraoral scanners to capture high-resolution images of your teeth, allowing for digital modelling and immediate fabrication.

This process reduces human error and shortens chair time significantly. Materials such as resin and ceramics are employed to achieve both durability and a natural appearance. After printing, the prosthetics require minimal finishing before placement.

One standout benefit: If you break a bridge or crown, digital files make replacement simple and fast. It also allows for greater customisation, important for comfort and bite alignment.

Tip: Ask your dentist if their practice uses digital impressions, as they improve fit and reduce discomfort compared to traditional moulds.

Dentures

3D printing offers fully customisable dentures that adapt closely to your bone structure and oral anatomy. This method eliminates the trial-and-error adjustments common with conventional dentures.

During production, the dentist scans your mouth, then designs the base and artificial teeth using software. The printed result comes with improved fit and stability, so sores and slipping are less likely.

You’ll also benefit from enhanced aesthetics, with teeth matched to your desired shade and shape. In case you lose your dentures, having the digital blueprint available means you won’t need repeat impressions.

Fun fact: Some practices can print a temporary denture in just a few hours—ideal if you need a quick solution.

Implants and Surgical Guides

When placing dental implants, precision is critical, and 3D printed surgical guides help your dentist achieve it. These guides are tailored for your mouth’s exact contours, directing tools accurately during surgery.

The planning phase relies on digital imaging, which is used to design the guide and pre-plan implant positions. This can reduce surgery time and lower your risk for complications.

3D printing also helps create custom abutments and temporary implant restorations. The made-to-measure approach leads to better integration with your bone and faster healing.

Hint: If you’re considering implants, ask about 3D printed guides—they improve predictability and safety during surgery.

Benefits and Challenges of 3D Printing in Dental Prosthetics

3D printing introduces new levels of precision, speed, and flexibility to dental prosthetics manufacturing. However, it also brings unique considerations, such as equipment costs and the need for specialised training.

Increased Customisation and Precision

With 3D printing, you can offer dental prosthetics that fit your patient’s mouth with remarkable accuracy. Digital scanning and design allow for truly custom crowns, bridges, dentures, and aligners that match an individual’s anatomy.

The use of digital workflows reduces the risk of manual errors. Even the most complex cases, such as full-arch restorations, can benefit from digital modelling and additive manufacturing. This leads to improved clinical outcomes and often increases patient satisfaction.

A fun fact: Digital impressions used for 3D design are often more comfortable for patients compared to traditional moulds. You can tweak and adjust the model digitally before manufacturing, saving both time and resources.

Efficiency and Reduced Turnaround Time

3D printing streamlines the process from scan to finished prosthetic. Once digital data is captured, you can print a prototype or a final restoration within hours, rather than waiting days or weeks for traditional methods.

Same-day prosthetics become feasible, letting patients save time with fewer appointments. Changes and adjustments are easier, as you simply edit the digital file and reprint, without remoulding or recasting.

While speed depends on the printer and material, a typical dental crown can be ready in under two hours. For clinics, this means you can handle more cases in less time, increasing both efficiency and patient throughput.

Cost Considerations

Although the initial investment for a high-quality dental 3D printer can be substantial — often upwards of £12,000 ($15,000) — running costs per print are typically lower than traditional lab methods.

You will benefit from reduced material waste, especially as additive manufacturing uses only what is required. Labour costs also decrease, as fewer manual steps are needed.

However, ongoing expenses include materials, maintenance, and training staff to operate and design using the software. Choosing the right 3D printer and material for your specific workflows is crucial to maximising savings and avoiding hidden costs.

Future Developments and Industry Trends

With rapid progress in dental materials, digital workflows, and manufacturing standards, 3D printing is set to make dental prosthetics more precise, accessible, and tailored. The focus has shifted towards biocompatible innovation, full digital integration, and robust safety measures.

Emerging 3D Printing Materials

You can expect to see a broader range of printable dental materials, each engineered for specific prosthodontic requirements. Biocompatibility and mechanical strength remain key, with new resins and polymers designed to mimic natural tooth structure and gum tissue.

Ceramic- and metal-based printing is advancing, allowing custom crowns, bridges, and partial dentures with high wear resistance. Materials like hybrid composites provide greater flexibility and improved aesthetics. Companies have started releasing printable materials that can withstand daily oral forces and temperature changes from food and drinks.

Tip: Always verify that the material used in your dental prosthetic is certified for medical use, and if you have allergies, discuss options with your dentist. For dental labs, investing in versatile printers compatible with a wide array of resins and metals will help you adapt to changing patient needs and requests.

Integration with Digital Dentistry

A fully digital workflow — from intraoral scanning to CAD/CAM design and 3D printing — is becoming standard in modern dental clinics. You can now get prosthetics designed and fitted with fewer appointments and more predictability in final fit and appearance.

3D-printed surgical guides, custom trays, and root analogue implants have become more prevalent. These tools help reduce chair time and improve treatment outcomes. By combining CBCT scans and digital impressions, precise geometries are created to match individual mouths, minimising the need for manual adjustments later.

For dental professionals, upgrading to digital impression systems and training in software design bring major productivity gains. This not only speeds up turnaround but also reduces the risk of human error. Clinics embracing digital dentistry gain a strong competitive edge.

Regulatory and Ethical Considerations

Strict regulatory oversight ensures ongoing improvements in patient safety for 3D printed dental prosthetics. All materials and production processes must comply with local and international medical device standards. The Medicines and Healthcare products Regulatory Agency (MHRA) in the UK, for example, evaluates both material biocompatibility and the accuracy of digital workflows.

Ethical considerations include data privacy for personal digital dental records and the proper handling of patient-specific files. Dentists must store digital scans securely and comply with all applicable consent and data protection regulations.

You should also be aware of certification requirements before purchasing printed prosthetics. Always ask your dental provider about approval status, traceability, and warranties for any device made using 3D printing in dentistry.

Frequently Asked Questions

You can now receive dental prosthetics that fit better, look more natural, and are created much faster than before. Modern 3D printing streamlines dental workflows, expands material choices, and makes customisation much easier for both patients and dentists.

What advancements have been made in dental prosthetics due to 3D printing?

3D printing allows dental technicians to produce crowns, bridges, and dentures with higher precision than traditional techniques. The digital workflow lets you preview dental prosthetics using virtual models before fabrication even begins.

It is now possible to fabricate multiple components at the same time, speeding up the entire process. Many labs use 3D scanning and digital design, meaning you can get replacements that fit accurately the first time.

In what ways does 3D printing enhance the production of dental implants?

With digital impressions and 3D printers, dental implants are created to match your exact oral anatomy. 3D printing can produce surgical guides for implant placement, improving accuracy and safety.

Dentists can print models for diagnosis, surgical templates, and final prosthetics, all using your unique data. Rapid prototyping also allows for quicker adjustments and remakes if needed.

What are the benefits of using 3D printing for dental prosthetic fabrication?

You benefit from shorter turnaround times—sometimes same-day or next-day delivery of crowns and bridges. 3D printing also reduces material waste and streamlines manual steps, making treatment more cost-effective.

New materials, like printable ceramics and resins, come in shades and translucencies that closely replicate real teeth. 3D printers can layer these precisely, producing natural-looking results.

How has patient experience improved with the introduction of 3D-printed dental prosthetics?

You can experience less time in the dental chair because digital impressions replace messy moulds. Appointments often require fewer visits since design tweaks and final adjustments happen rapidly on a computer.

Printed prosthetics generally offer a better fit, meaning fewer modifications are required once your new teeth are ready. Patients also report greater comfort and more confident smiles when prosthetics match their natural teeth shape and colour.

What materials are commonly used in 3D printing for dental prosthetics, and why?

Dental 3D printers primarily use biocompatible resins, hybrid composites, and ceramics. These materials are chosen because they are strong, durable, and safe for long-term wear in your mouth.

Ceramic and zirconia parts are suitable for visible teeth thanks to their natural colour and shine. Resins allow flexible printing and are perfect for creating denture bases and temporary crowns.

How does 3D printing contribute to personalised dental solutions?

Your dental restoration begins with digital scanning, capturing the exact shape of your gums and teeth. Technicians design your prosthetic down to a fraction of a millimetre, ensuring a proper bite and improved aesthetics.

The customisation extends to shade matching, anatomical contours, and even how your teeth function when you chew. If you have unique dental needs, such as a challenging bite or missing several teeth, 3D printing can create a solution tailored just for you.