Prolonging Dental Equipment Lifespan: Maintenance Strategies for Enhanced Practice Efficiency

Posted on: 02/06/2025

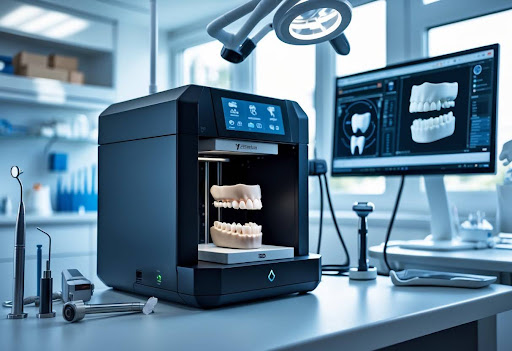

Regular dental equipment maintenance is the key to prolonging its lifespan, keeping your investments reliable and your patients safe. Routine cleaning, calibration, and inspection help you catch minor issues before they become costly breakdowns. For example, cleaning a dental chair’s surfaces daily and servicing handpiece turbines on schedule are simple steps that make a significant difference.

You avoid expensive repairs and unpredictable downtime by committing to care routines like planned preventative maintenance. Fun fact: well-maintained equipment can outlast its expected service life by several years, saving thousands in replacements. You also ensure that your practice runs smoothly and continues to meet high standards.

Use practical strategies such as quick daily wipe-downs, regular inspections, and keeping detailed maintenance logs. Small, consistent actions help extend your dental equipment’s performance, reduce unexpected expenses, and create a safer environment for everyone in your practice.

Understanding Dental Equipment Lifespan

Dental equipment lifespan depends on a blend of usage, care, and specific machine design. Choosing the right maintenance strategies and understanding equipment traits can make a difference of years in usability.

Key Factors Affecting Longevity

How you handle and care for your equipment directly impacts its longevity. Daily and periodic cleaning, following manufacturer’s instructions, and using compatible lubricants are essential. Even minor lapses like using the wrong cleaning agent may lead to corrosion or performance issues.

Environmental factors matter too. Placement in areas with extreme temperatures, high humidity, or exposure to chemical fumes accelerates wear. Routine inspections help spot issues early, preventing costly breakdowns.

Here are a few tips to get the most out of your gear:

- Keep accurate maintenance records for each item.

- Train staff in best handling practices.

- Replace worn components promptly.

- Schedule planned maintenance, not just repairs.

Typical Life Expectancy by Equipment Type

Lifespan varies widely depending on the equipment. For example, dental handpieces—when properly maintained—can last up to 5–7 years or longer. Suction units generally operate reliably for about 10 years if serviced regularly.

Ultrasonic scalers and curing lights tend to have lives between 5–8 years. Compressors and dental chairs, when maintained well, may last 10–15 years. Sterilisers typically show wear after 7–10 years of use.

Daily and Routine Maintenance Best Practices

Consistent daily maintenance not only supports patient safety but also preserves vital components in your dental equipment. Focusing on specific cleaning, inspection, and handling habits helps you avoid unexpected breakdowns and long-term costs.

Proper Cleaning and Disinfection Techniques

Start and end each day by thoroughly wiping down surfaces with a manufacturer-recommended cleaning agent. Use disposable wipes or microfibre cloths for dental chair arms, light handles, and touch panels. Rinse and sterilise small detachable components like suction tips and handpieces in an autoclave if compatible.

For waterlines, flush them with approved solutions for at least two minutes to reduce biofilm. Tip: Change water bottle reservoirs daily and air-dry them completely before refilling to discourage bacterial growth. Check for chemical residue or odours, which signal inadequate rinsing.

Never let organic material dry on instruments; pre-soak immediately after use. Remember to separate items clearly labelled as single-use to avoid accidental cross-contamination.

Daily Inspection Protocols

Perform a quick visual check on all critical equipment at the start of your shift. Examine handpieces, hoses, power cords, and connection ports for signs of cracking, fraying, or residue buildup. Small cracks or leaks often indicate a need for prompt repair.

Test the chair’s movement, lights, and X-ray arms for smooth operation. Listen for unusual noises or any sluggishness. Make note of low-pressure readings on units and replace faulty bulbs or filters immediately.

Document findings in a daily logbook, and flag anything unusual for the next scheduled professional maintenance. Hint: Use a checklist to save time and ensure nothing is overlooked, even on busy mornings.

Safe Operation and Handling Procedures

Handle all handpieces and tools with care, using both hands whenever possible to prevent accidental drops. Always disconnect electrical equipment before cleaning to reduce injury risk, and avoid bending cables sharply.

Store each instrument in its designated tray or rack, keeping sharp ends pointed away from access points. Do not overload autoclaves or ultrasonic cleaners; follow manufacturer guidelines closely for load size and cycle duration.

When moving larger equipment, lock wheels first and ask for assistance to prevent tipping or cord strain. Teach all staff members the correct start-up and shutdown procedures for every machine in use, reviewing protocols regularly to stay updated with any changes.

Preventive Maintenance Strategies

Consistent preventive maintenance plays a vital role in extending the lifespan of your dental equipment. Focusing on scheduled servicing and timely replacement of consumables can help you avoid sudden breakdowns, improve workflow, and protect your investment.

Scheduled Servicing and Calibration

Routine inspections and calibration help maintain equipment accuracy and safety. For instance, autoclaves should be checked and calibrated at least once every six months to ensure proper sterilisation. Dental chairs and delivery units also need inspection to prevent hydraulic or electrical failures.

Create a maintenance schedule using a simple table or calendar, including dates for technician check-ups and calibration tasks. Many manufacturers provide recommended service intervals in their manuals—always follow these guidelines for best results.

Tip: Keep detailed servicing records for each piece of equipment. This helps in tracking wear patterns and scheduling future maintenance proactively.

Replacing Consumable Parts

Consumable items such as handpiece turbines, suction filters, hoses, and O-rings wear out faster than other components. Handpieces, for example, may require new turbines after approximately 6–12 months, depending on usage levels.

Replace filters in suction machines every 1–3 months to maintain consistent performance. Neglecting this step increases the risk of breakdowns and reduces suction efficiency.

Hint: Stock spare consumables for high-use items. This minimises downtime and ensures your clinic maintains an uninterrupted workflow.

A checklist for consumable replacements includes:

- Handpiece turbines

- Water and air filters

- Suction hoses

- Gaskets and O-rings

Prioritise replacing consumables at regular intervals rather than waiting for problems to appear. This approach helps maintain smooth, efficient clinic operations and prevents emergency repairs.

Staff Training and Maintenance Culture

A proactive approach to dental equipment maintenance relies on both informed team members and well-established routines. Consistent training and a clear maintenance structure minimise costly breakdowns and keep critical tools in top condition.

Educating Dental Teams on Equipment Care

Training all staff on daily, weekly, and monthly equipment protocols prevents mishandling and improper cleaning. Regular workshops—scheduled biannually—offer hands-on demonstrations for new tools and refresher courses for seasoned staff. You can provide laminated checklists in each treatment room to reinforce these steps.

Make sure your training programme covers key topics:

- Correct disassembly and reassembly procedures

- Use of approved cleaning chemicals (avoid bleach or abrasive agents)

- Recognising signs of wear and alerting supervisors

A fun fact: improper use of disinfectants is one of the leading causes of premature handpiece failure. Never skip cooldown periods for autoclaves—rushing cycles decreases lifespan. Encourage questions during sessions to boost understanding, and use visual aids for clarity.

Establishing Accountability and Documentation

Designate specific roles for equipment inspection and assign a "maintenance lead" for each shift. Use a simple logbook or digital spreadsheet to record:

- Daily cleaning

- Weekly lubrication

- Calibration dates

- Reported issues and resolutions

Insist logs are signed and dated. A quick table at the staff station showing who completed which task adds transparency. Rotate roles quarterly to spread knowledge and avoid fatigue.

Provide rewards for teams with perfect documentation for six months, such as an office lunch. Regular reviews of the records help you spot patterns, like recurring faults with certain tools, allowing early intervention. This structure creates a team culture where everyone takes ownership of equipment longevity.

Troubleshooting and Addressing Common Issues

Routine troubleshooting and swift responses to problems keep dental equipment reliable and extend operational life. Recognising early signs and reacting effectively helps prevent small faults from evolving into expensive breakdowns.

Identifying Early Signs of Wear and Malfunction

Spotting problems early is crucial. Frequent signs include unusual noises, increased vibration, or changes in performance like slower handpieces or waterline flow. Worn seals or leaking gaskets can create puddles or stains around dental units.

Visual inspections are effective. Examine tubing, connectors, and handpiece couplings for cracks, discolouration, or debris. Check air compressors and suction units for decreased pressure or inconsistent suction, which often hints at a clogged filter or worn motor.

Tip: Keep a maintenance log. Record every irregular sound, leak, or alert from display panels; patterns help identify persistent issues before they worsen.

Effective Response to Equipment Failures

When a fault arises, act swiftly but safely. Switch off and unplug the equipment; this prevents electric shocks and further damage. Refer to the manufacturer’s manual for basic troubleshooting steps or fault codes shown on the display.

Common quick fixes include tightening loose hoses, replacing O-rings, and clearing debris from valves or nozzles. For persistent issues like recurring power failures or overheating, contact a certified technician. Attempting complex repairs without proper training often voids warranties.

Useful checklist:

- PPE before inspection

- Isolate and unplug device

- Reference error codes/manual

- Tidy work area and remove debris

- Call a professional if problems persist

Prompt action and knowing your limits prevent downtime and support the longevity of your dental equipment.

Frequently Asked Questions

Proper dental equipment care includes routine maintenance, careful handling, and adherence to specific cleaning protocols. Maintaining optimal equipment performance reduces breakdowns and extends the useful life of your instruments.

What are the best practices for sterilising dental instruments to maximise their longevity?

Always clean instruments immediately after use to remove debris. Use a gentle brush and approved detergent to prevent corrosion. Ensure instruments are completely dry before placing them in an autoclave, as moisture speeds up oxidation.

Avoid stacking or overloading trays in your steriliser. By giving instruments enough space, you reduce the risk of warping or damage. Allow enough time for instruments to cool before handling them after each cycle.

How can regular equipment calibration contribute to extending the lifespan of dental tools?

Calibrating dental equipment sets accurate operational parameters. This allows handpieces, autoclaves, and imaging devices to work within manufacturer-defined specifications. Scheduling biannual or quarterly calibration checks can help spot mechanical drift early.

Routine calibration ensures that drills run at correct speeds, ultrasonic scalers operate efficiently, and X-ray machines deliver precise exposures. This reduces wear and minimises the risk of premature component failure.

What storage conditions are recommended to prevent premature deterioration of dental equipment?

Store sensitive equipment like handpieces and curing lights in a cool, dry environment. Excess humidity can encourage rust and microbial growth. Avoid direct sunlight, which degrades plastics and rubber parts over time.

Use padded cassettes or designated holders to prevent accidental drops and scratches. If you must store anything long-term, remove batteries and lubricate moving components beforehand.

How does adherence to manufacturers' guidelines affect the lifetime of dental apparatus?

Following manufacturer instructions on cleaning, lubrication, and maintenance preserves warranties and optimises device performance. Most manuals include step-by-step care routines tailored to each model.

You might find that a manufacturer specifies a certain type of lubricant or restricts the use of common solutions like chlorine-based disinfectant, which could corrode metals or plastics. Overlooking these instructions shortens equipment life and can void warranties.

Can the implementation of a routine maintenance schedule reduce the need for frequent dental equipment replacements?

Routine maintenance, such as daily cleaning, lubrication, and scheduled filter changes, helps prevent sudden failures. Keeping a monthly checklist can catch minor issues like worn O-rings or filter clogging before they escalate.

Set reminders for professional servicing every six to twelve months. This proactive approach can add several years to the operational lifespan of vital equipment such as chair units, compressors, and vacuum systems.

What role does the quality of cleaning agents play in maintaining the condition of dental devices?

High-quality, pH-balanced cleaning agents protect delicate surfaces and mechanisms from abrasive damage or chemical corrosion. Inferior products may leave residues, hastening rust or damaging seals.

Always use agents that are recommended by the equipment manufacturer. For example, handpieces benefit from non-oily, residue-free sprays that won’t gum up internal bearings. Choose wipes and sprays proven to be safe for both stainless steel and plastic housings.